Trusted partner for high-quality wires & cables. Contact Us Today

3 Core Submersible Flat Cable (ISI)

- Home

-

/ 3 Core Submersible Flat Cable (ISI)

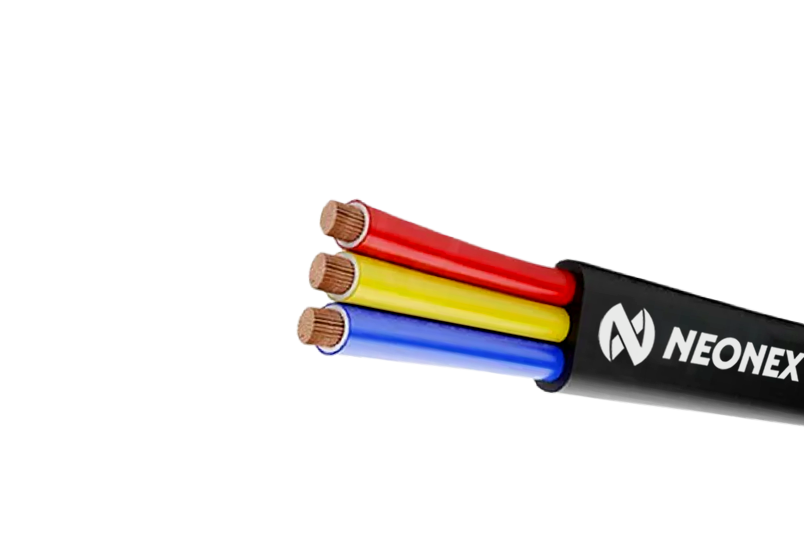

3 Core Submersible Flat Cable (ISI)

PRODUCT DESIGN | |

APPLICABLE STANDARD | IS 694:2010 |

CONDUCTOR | THE CONDUCTORS ARE DRAW FROM 99.97 % BRIGHT ELECTROLYTIC GRADE COPPER WITH MORE THAN 100%CONDUCTIvITY ARE ANNEALED AND BUNCHED TOGETHER (CLASS 2 &5) 1S 8130 |

INSULATION PVC | THE BUNCH CONDUCTORS ARE INSULATED WITH SPECIALLY FORMULATED PVC COMPOUND WITH A HIGH INSULATION RESISTANCE VALUE. |

SHEATH PVC | THE OUTER SHEATH OF THE CABLE IS MADE FROM A SPECIAL GRADE OF ABRASION RESISTANT PVC COMPOUND IMPERVIOUS TO WATER, GREASE, OIL ETC. |

OPERATING TEMPERATURE RANGE: | TEMP -15°C TO MAX. + 70°C / + 85°C |

COLOUR | BLACK, GRAY (AND ALSO OTHER COLOUR REQUEST ON CUSTOMER) |

PACKING | 500m & 1000m. (+/-5%) HIGHER LENGTH AVAILABLE ON REQUEST. |

MARKING | THE CABLES ARE PRINTED WITH GENERIC MARKING "NEONEX CABLES 3 CORE FLAT CABLES" |

APPLICATION | - A SUBMERSIBLE PUMP CABLES SPECIALIZED PRODUCT TO BE USED FOR SUBMERSIBLE PUMPS IN A DEEP WELL. |

- NEONEX CABLES 3 CORE SUBMERSIBLE FLAT CABLES ARE MANUFACTURED FOR DESIGNED FOR USE IN UNDERGROUND, UNDER-WATER OR ON WET SURFACE. | |

FEATURE | - MANUFACTURED FROM BRIGHT ANNEALED 99.97 % PURE COPPER CONDUCTORS AND HENCE, OFFER LOW CONDUCTOR RESISTANCE. |

- OUTER SHEATH CONSISTS OF HIGHLY ABRASION RESISTANT PVC COMPOUND IMPERVIOUS TO GREASE, OIL AND WATER ETC | |

- VERY GOOD INSULATION PROPERTIES WHEN SUBMERGED IN WATER | |

- EXCELLENT MECHANICAL AND ELECTRICAL PROPERTIES. | |

- PROGRESSIVE SEQUENTIAL LENGTH MARKING ON EVERY METER. | |

ISO CERTIFICATION | ISO 9001:2015, ISO 45001:2018, ISO 14001: 2015, CE, RoHS |

PRODUCT CERTIFICATION | IS 694:2010 IS 7098 P-1 TUV RHEINLAND CERTIFICATE No. R 60160877 |

TECHNICAL DATA | |||||||

NOMINAL CROSS SECTIONAL AREA OF CONDUCTOR | NUMBER/ NOMINAL DIA OF WIRES (MAX.) | NOMINAL THICKNESS OF INSULATION | NOMINAL THICKNESS OF SHEATH | OVERALL DIMENSION (W X H) | MAXIMUM DC RESISTANCE OF CONDUCTOR AT 20° C | MAX. CURRENT CARRYING CAPACITY | |

mm2 | Nos./mm | mm | mm | WIDTH (mm) | HEIGHT (mm) | Ω/km | Amps |

3C X 1* | 14/0.3 | 0.6 | 0.9 | 10.50 | 4.90 | 18.1 | 12 |

3C X 1.5* | 22/0.3 | 0.6 | 0.9 | 11.40 | 5.20 | 12.1 | 14 |

3C X 2.5* | 36/0.3 | 0.7 | 1.0 | 13.20 | 6.00 | 7.41 | 18 |

3C X 4.0 | 56/0.3 | 0.8 | 1.0 | 15.40 | 7.00 | 4.95 | 26 |

3C X 6.0 | 84/0.3 | 0.8 | 1.1 | 18.40 | 8.00 | 3.30 | 31 |

3C X 10.0 | 140/0.3 | 1.0 | 1.4 | 22.20 | 9.60 | 1.91 | 42 |

3C X 16.0 | 224/0.3 | 1.0 | 1.4 | 27.40 | 11.60 | 1.21 | 57 |

3C X 25.0 | 354/0.3 | 1.2 | 2.0 | 34.10 | 14.30 | 0.780 | 72 |

3C X 35.0 | 495/0.3 | 1.2 | 2.0 | 37.60 | 15.80 | 0.554 | 90 |

3C X 50.0 | 703/0.3 | 1.4 | 2.2 | 44.00 | 18.20 | 0.386 | 115 |

3C X 70.0 | 988/0.3 | 1.4 | 2.2 | 51.20 | 21.00 | 0.272 | 143 |

NOTE:

- THE NUMBER OF WIRES AND DIAMETER MENTIONED IN THE TABLE ARE APPROXIMATE AND NOMINAL, HOWEVER THEY SHALL MEET THE REQUIREMENTS OF CONDUCTOR RESISTANCE AS PER STANDARDS. IS 8130

- TOLERANCE: UP TO 4.0 SQ MM +/-0.5 MM. 6.0 SQ MM & 10 SQ MM +/-1.0 MM AND ABOVE 10 SQ MM +/-1.2 MM

- THE ABOVE DATA IS INDICATIVE AND MAY BE REVISED WITHOUT PRIOR INFORMATION. NEONEX CABLES WILL NOT BE LIABLE FOR ANY DAMAGES ARISING OUT OF INCORRECT APPLICATION.

×

×